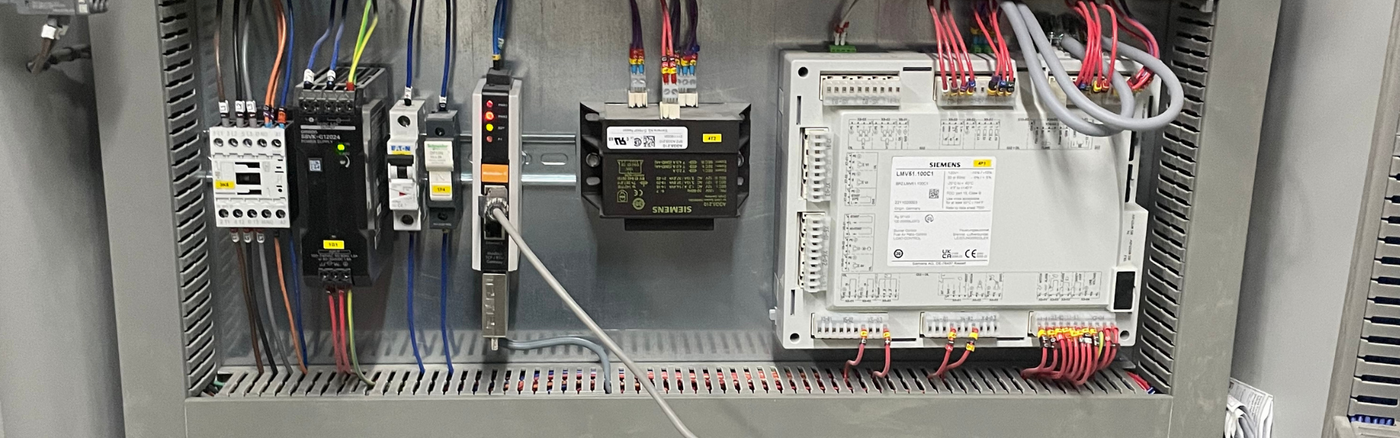

Siemens LMV Burner Management Systems: Advanced Control for Optimal Industrial Combustion

The Siemens LMV (Linkage-less Burner Management System) offers cutting-edge solutions for the precise control and optimisation of industrial burners. These sophisticated systems ensure the safe, reliable, and efficient combustion of fuels, making them essential for industrial heating processes.

Key Functions of Siemens LMV Burner Management Systems

1. Comprehensive Burner Control

The LMV system precisely manages burner operations, regulating fuel and air supply to achieve optimal combustion conditions. By monitoring and adjusting parameters such as fuel flow rate, air-to-fuel ratio, and flame stability, it ensures efficient and consistent combustion.

2. Enhanced Safety Features

Safety is paramount in burner management. The LMV system includes multiple safety mechanisms to prevent hazardous conditions such as fuel leaks, flame failure, or excessive temperatures. It continuously monitors burner operations, initiating safety shutdowns during abnormal conditions to protect personnel and equipment.

3. Reliable Ignition Control

Ensuring a controlled and reliable ignition sequence, the LMV system monitors flame detection and verifies successful ignition. In the event of flame failure, it implements appropriate safety measures.

4. Fuel and Air Optimisation

Designed to maximise combustion efficiency and minimise emissions, the LMV system optimises the fuel and air mixture by continuously adjusting burner parameters based on real-time measurements. This leads to improved energy efficiency, reduced fuel consumption, and a lower environmental impact.

5. Diagnostic and Maintenance Support

The LMV system offers advanced diagnostic capabilities and maintenance support, providing operators with real-time data on burner performance, alarms, and system health. This aids in proactive troubleshooting and maintenance planning.

6. Seamless Integration and Communication

Compatible with larger industrial automation systems, the LMV system supports various communication protocols, enabling seamless data exchange and process optimisation.

Siemens LMV Product Range

Siemens LMV2 and LMV3 Controllers

Both LMV2 and LMV3 models incorporate burner control, ratio control, and gas proving as standard, simplifying the overall burner management system. They include built-in variable programme sequences for gas or oil burners, with or without a pilot burner. The LMV3 is particularly suited for continuous operation with ionisation probes, ideal for steam boiler and process heat applications.

Siemens LMV5 Controllers

Building on the features of the LMV3, the LMV5 offers additional benefits such as load control, VSD control, and O2 combustion optimisation. The LMV52.4 model includes temperature-compensated flue gas recirculation for ultra-low NOx applications. The integrated load control, featuring a PID temperature/pressure controller, ensures a smoother cold start-up process for hot water or steam boilers, reducing wear and tear.

Integration with Siemens Actuators

The LMV controls are designed to work seamlessly with the Siemens SQM3 and SQM1 actuator ranges, ensuring accurate positioning of air and fuel dampers for optimal combustion. The system allows for variable actuator running times, providing faster start-up when there is a call for heat.

Advanced Features and Applications

-

CANBUS Interface: Utilised by LMV5 controls, the CANBUS interface supports multiple actuators across the burner, ideal for zoning and accommodating seasonal changes without cable length limitations.

-

Dual-Fuel Capability: Separate inputs and outputs for oil or gas operation enable accurate diagnostics and seamless dual-fuel operation without additional relays.

-

Optional Features: The LMV5 offers integrated load control, electronic safety limit thermostat, and O2 control functions, enhancing its suitability for various industrial applications.

Conclusion

The Siemens LMV Burner Management System combines advanced control algorithms, robust safety features, and diagnostic capabilities to ensure safe and efficient burner operation in industrial heating applications. With models such as the LMV2, LMV3, and LMV5, Siemens provides versatile and reliable solutions tailored to meet the diverse needs of industrial combustion processes.

Siemens LMV3 Details

Siemens LMV5 Details